Karolo ea li-colours tse nyane tsa pampiri ea pampiri e nang le thepa ea pampiri bakeng sa lihlahisoa tsa liphoofolo tsa lapeng

Tlhaloso

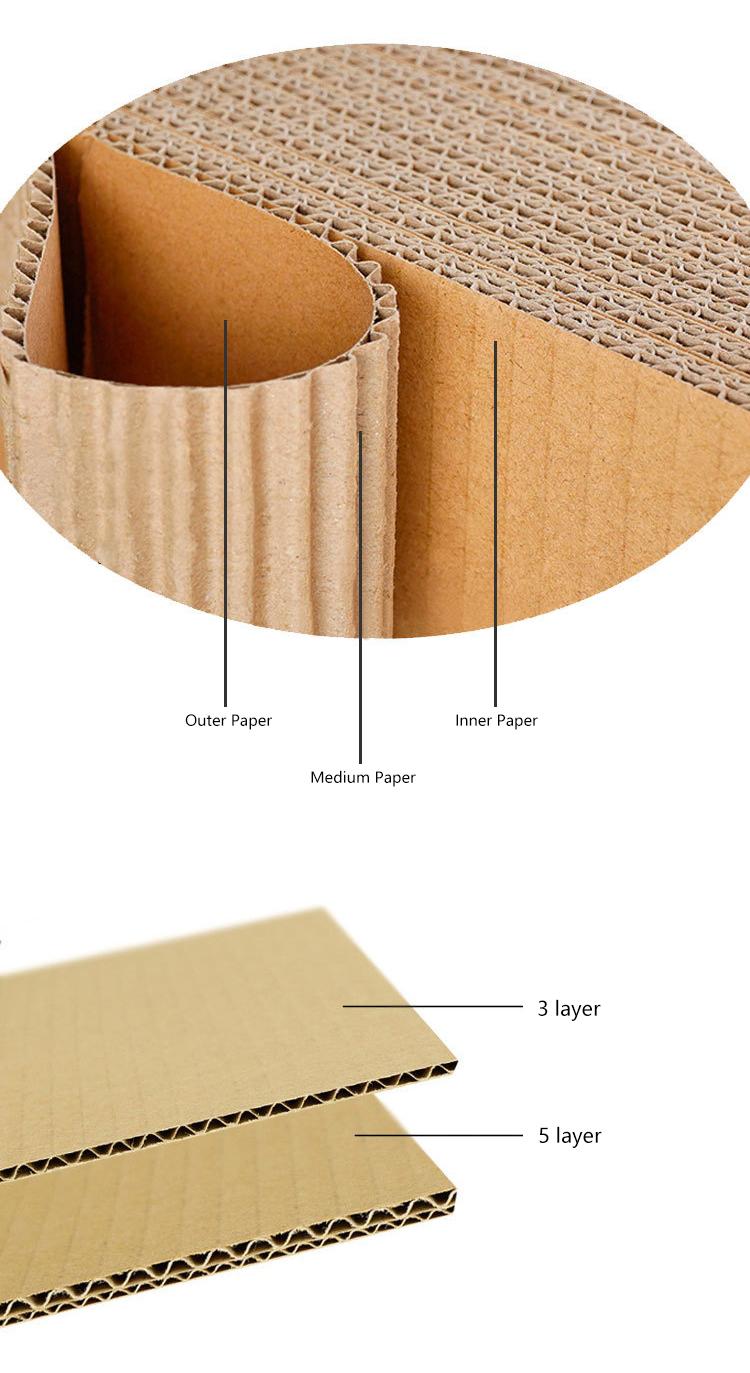

Ka lebaka la boholo bo nyane ba lebokose, lisebelisoa tse tlileng li entsoe ka lekopa. Khetho ea lisebelisoa e ka ipapisa le boima ba boima, boholo le tšebeliso ea sehlahisoa. Lintho tsena li na le pampiri e matla e nang le li-papper tse tharo ho 3 ply / 5 ply, ho lekana boima le boholo ba sehlahisoa sa limpho.

BLeseli la ASIC.

| PLebitso la Roduct | Lebokose le ka lengata le sehiloeng | Surface hantle | Glopsy Lague, Matte Lames UV, Stapting ea khauta |

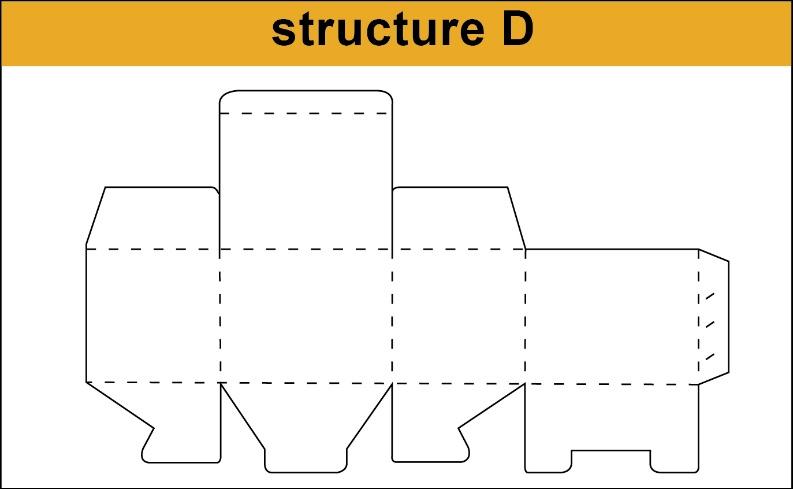

| Lebokose Setaele | Sebopeho d | LTlhahiso ea Ogo | Clogo ea USTotized |

| Lintho tse bonahalang Sebopeho | Break ea White Break+Board Board/ pampiri ea kraft | ORigin | Ningbo |

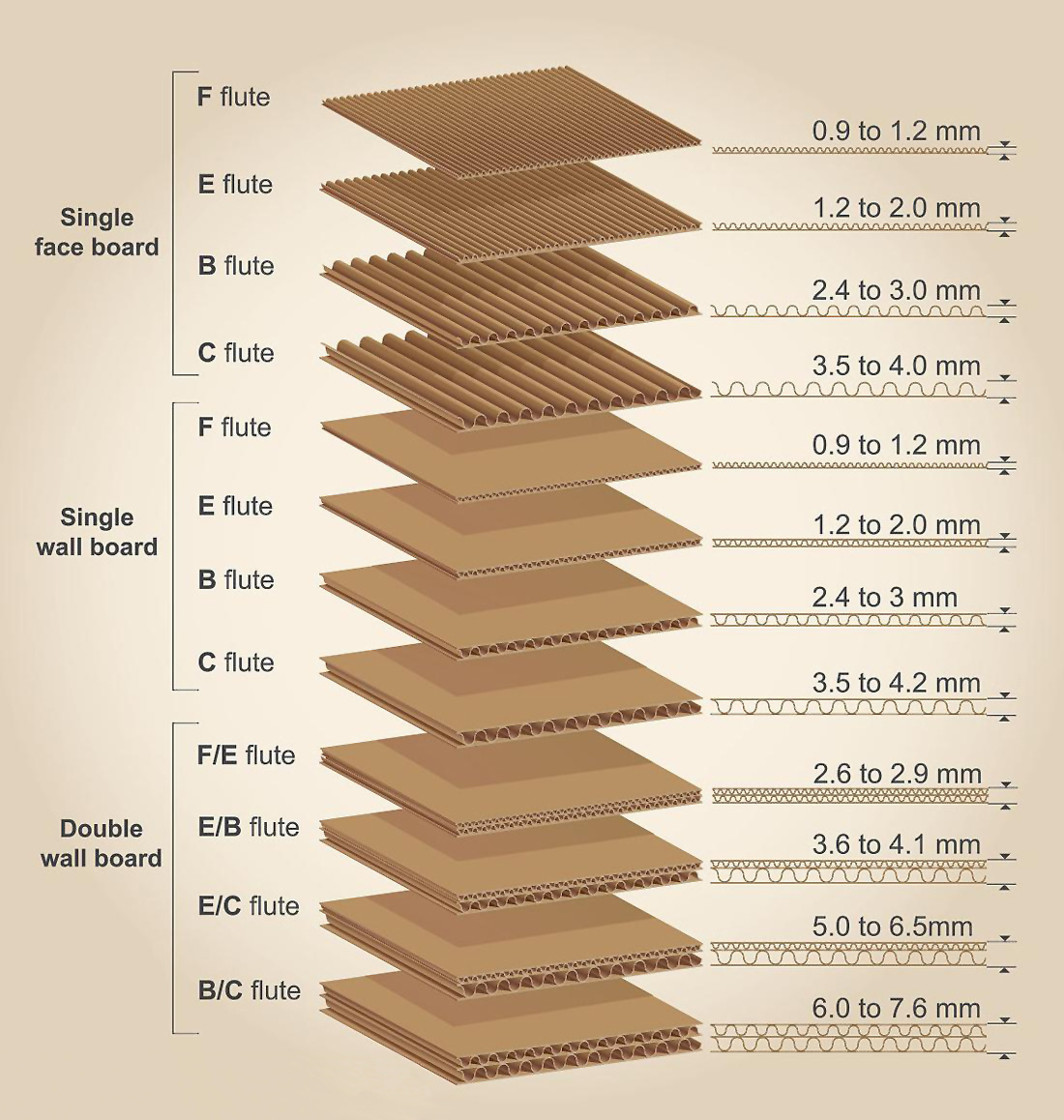

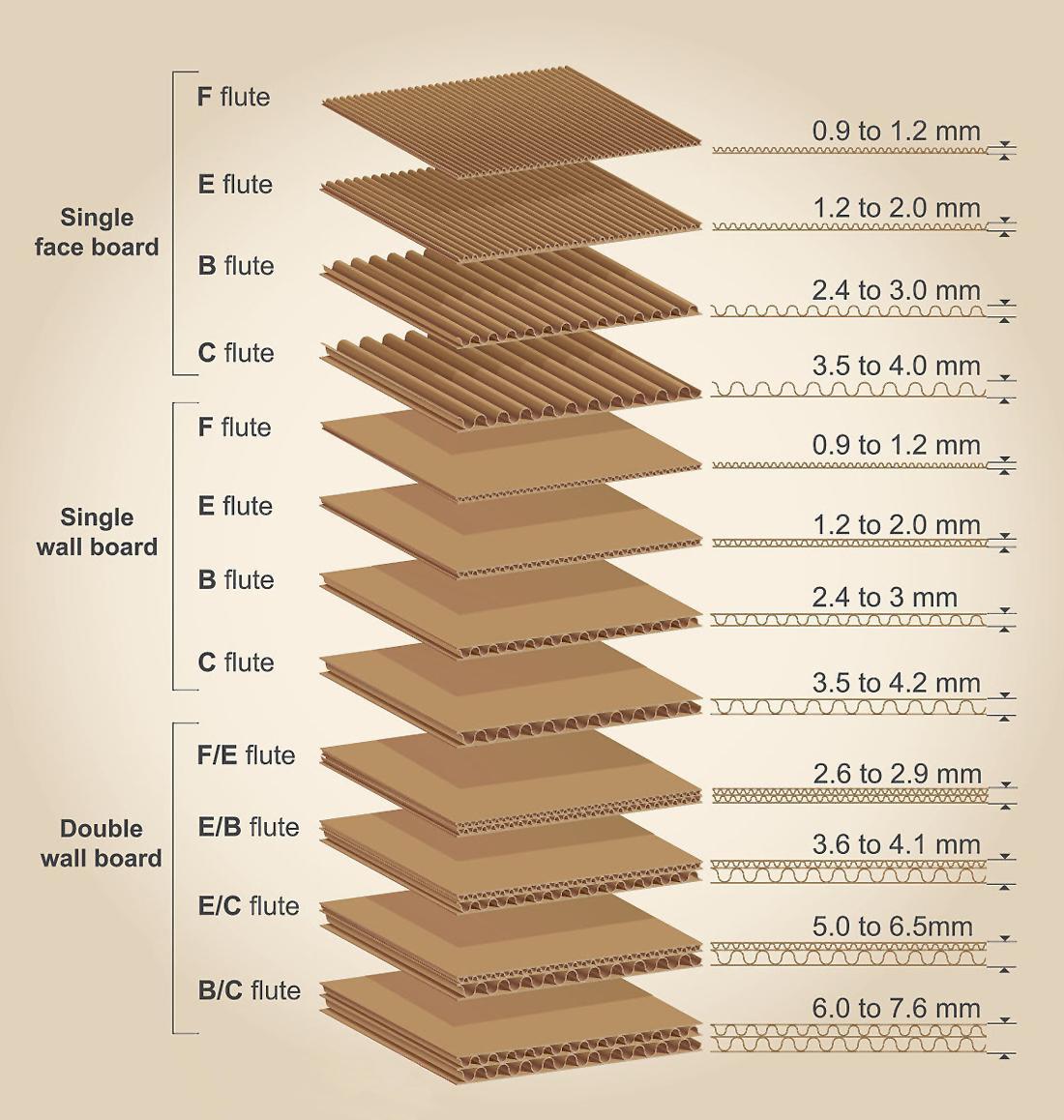

| Mofuta oa lekolu | E flute, B Flute, C Flute, BE Thusa | Sam | Amohela mehlala ea moetlo |

| Sebopeho sa sebopeho | REctalele | SNako e lekaneng | 5-8 matsatsi a ho sebetsa |

| Color | C'Mala oa myk,' mala oa tenene | PNako ea Tsamaiso ea Tsamaiso | 8-12 matsatsi a ho sebetsa ka bongata |

| Pho hlapa | TLHALOSO EA TLHOKOMELISO | TPackage ea Ransport | Matla5 plyCarton e koetsoeng |

| Mofuta | E le 'ngoeLebokose la khatiso | Moq | 2000pcs |

Litšoantšo tse qaqileng

Re na le sehlopha sa litsebi ho lekola sebopeho le boleng ba khatiso ea lebokose. Moqapi oa sebopeho o tla lokisa moralo le ho kuta mold ho latela lisebelisoa tse fapaneng.

Ka kopo buisana le ho buisana le morekisi mabapi le khetho ea lisebelisoa tsa pampiri le mekhoa ea khatiso.

Sebopeho sa thepa le ts'ebeliso

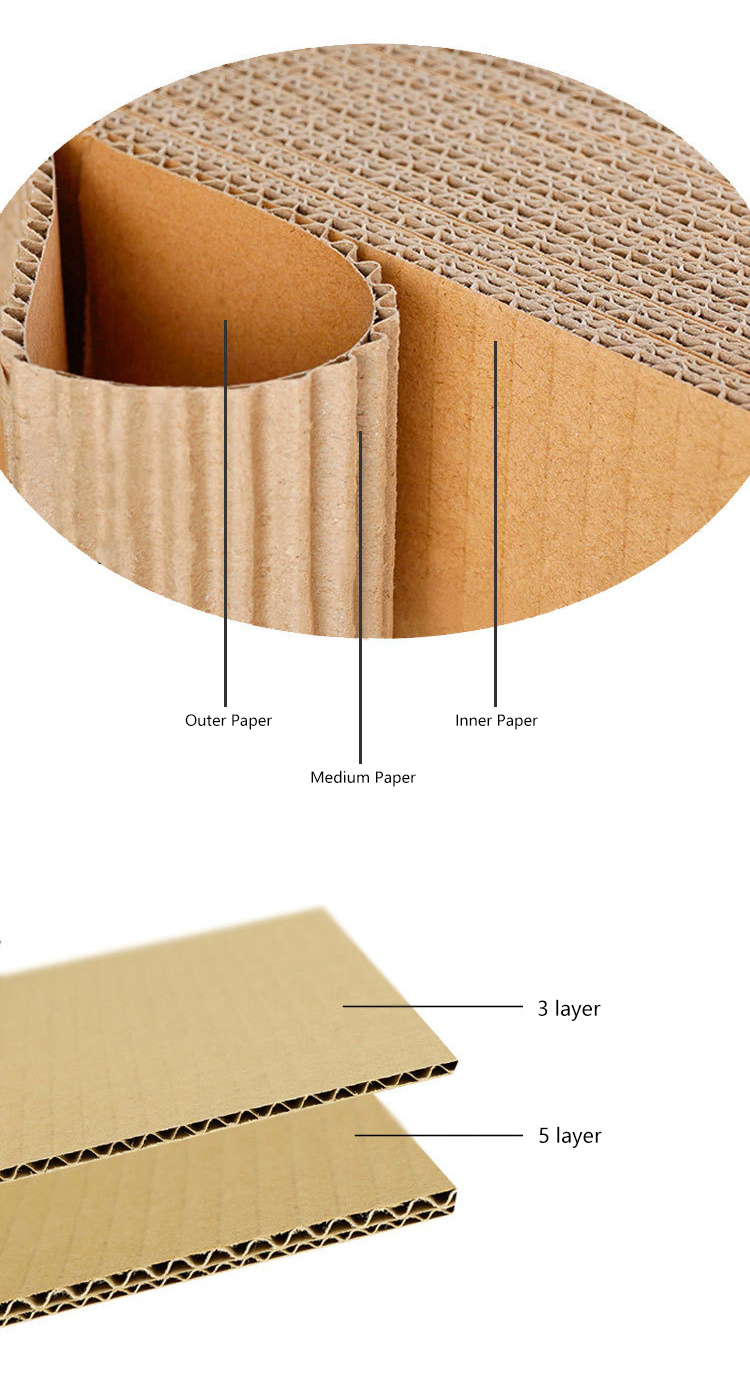

Mesebetsi ea likarete tse halikiloeng tse bolokiloeng ka libopeho tse fapaneng le tsona li fapane. Le ha pampiri e tšoanang ea ka ntle le pampiri e kahare e sebelisoa, ts'ebetso ea boto e sentsoeng e fapana ka lebaka la sebopeho se fapaneng se fapaneng.

Mefuta e atileng ea bongoana e le 'ngoe e le flute, B Flute le C Flute.

Ka tloaelo motsoako o habeli o tšetsoeng o kenyelletsa lekolilo, e-ba le mafura le ka bc

OLitefiso tsa pampiri ea UR: Boto ea Duplex ea Duplex ea Duplex.

Lintho tse kantle tsa pampiri: Pampiri e tšoeu ea karete e tšoeu, pampiri ea karete e ntšo, pampiri ea Kraft.

Lintho tse kantle tsa pampiri: Pampiri e tšoeu ea karete e tšoeu, pampiri ea karete e ntšo, pampiri ea Kraft.

Setšoantšo sa ts'ebetso sa karete ea karete e halikiloeng.

Litlhaloso tse botenya ba karete ea karete e putsoa.

Likopo tsa ho paka

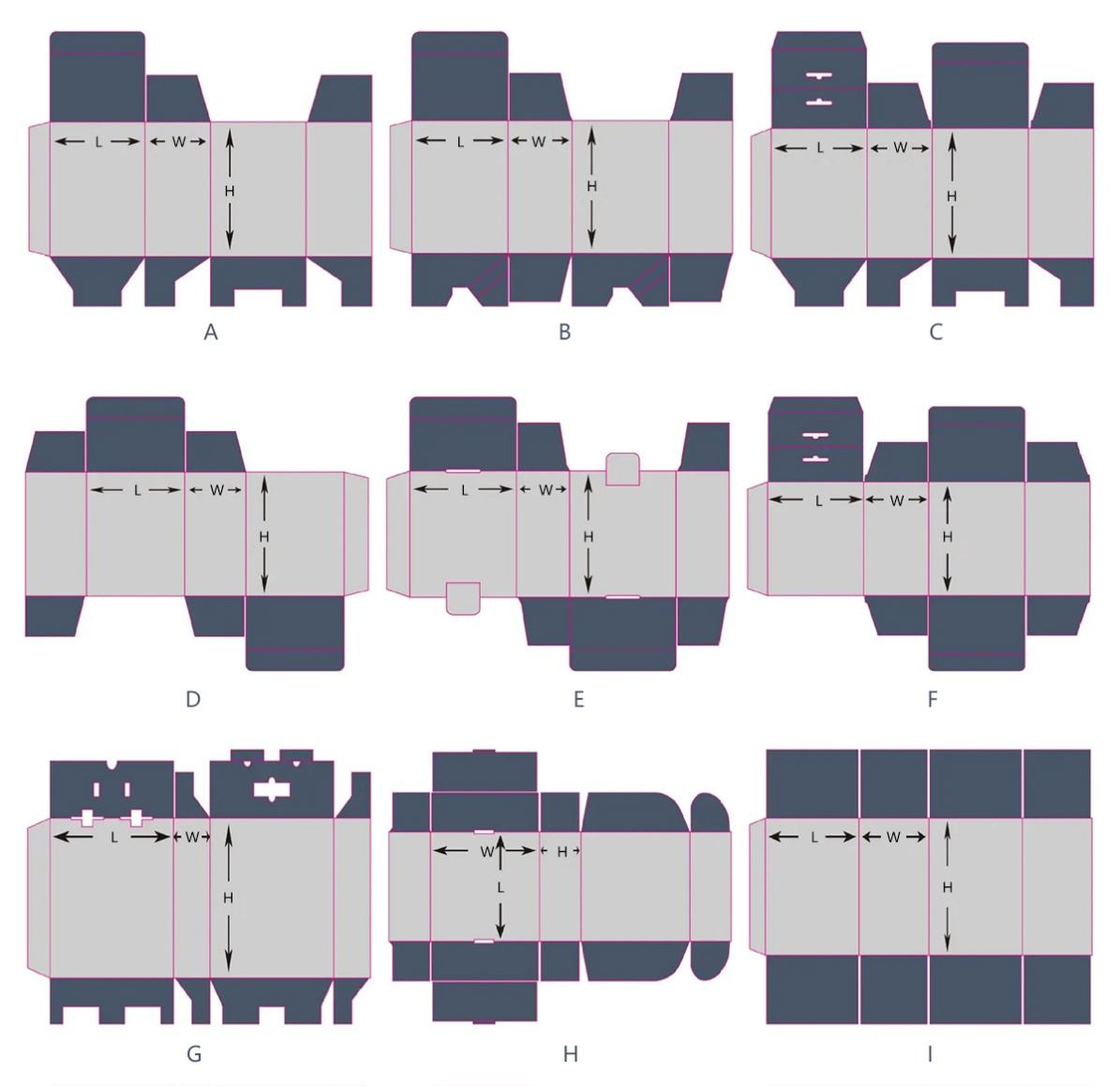

Mofuta oa lebokose le sebaka sa lebokose

Mofuta oa lebokose o latelang

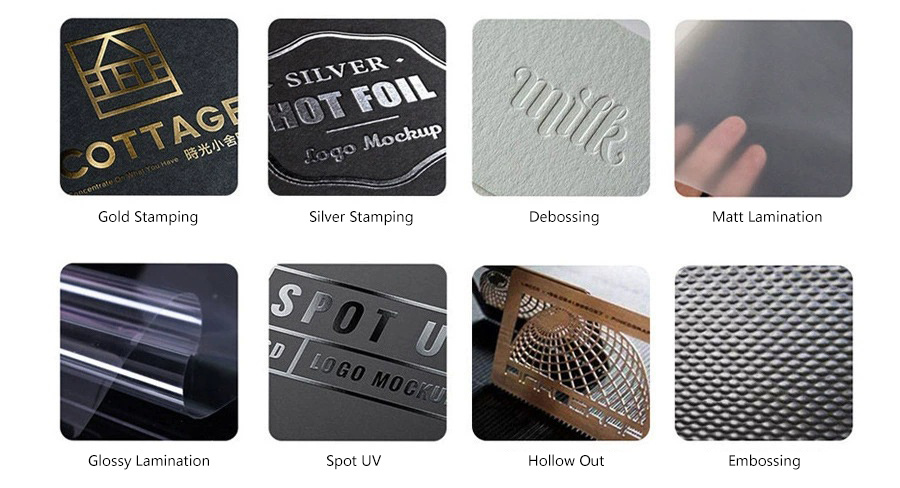

Ts'ebetso ea Phekolo ea Lefatše

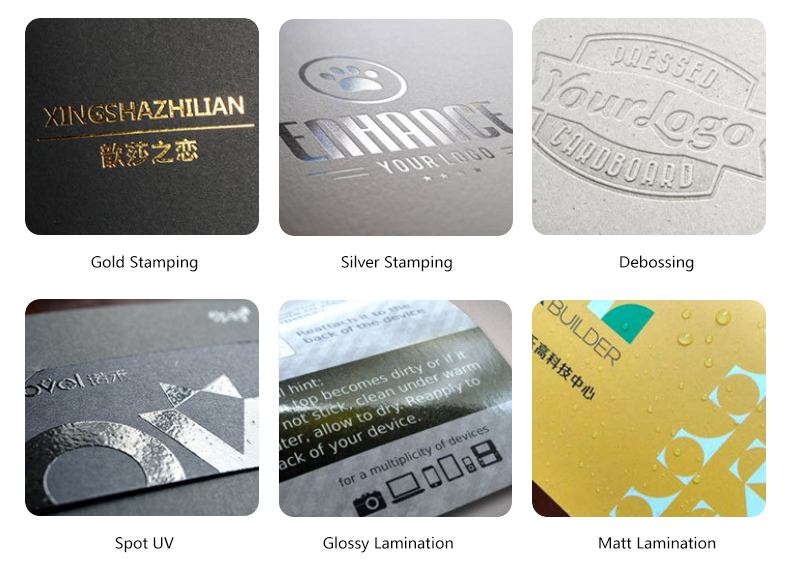

FOIL

Lithako tse matla li tla mebala e fapa-fapaneng, ho kenyelletsa khauta, khauta ea laer, silevera ea silevera ea laser, e ntšo, har'a ba bang.

LSetšoantšo

Ts'ebetso e buang e bua ka mochini o koahelang lifilimi ho koahela bokaholimo ba taba e hatisitsoeng ka sekhechana sa filimi ea polasetiki.

Ho koata

Concave le Convex ho etsa hore mochini oa khatiso oa liphallelo oa liphallelo oa liphallelo o felisitse lipaterone kapa litlhaku tse tharo tse fapaneng.

SPot Uv

Ka ho omella ka UV le ho folisa, enke e khanya ebile e khethehileng, haholo-holo bakeng sa matšoao a khoebo le litaba tsa khatiso.

Phekolo ea maemo a tloaelehileng joalo ka a latelang

Potso ea Bareki le Karabo

Ka kopo ikopanye le ts'ebeletso ea bareki bakeng sa tlhaiso-leseling e batsi.

Karabelo ea hau ea lipotso e tla re thusa ho khothaletsa sephutheloana se loketseng ka ho fetisisa.

Mesebetsi ea likarete tse halikiloeng tse bolokiloeng ka libopeho tse fapaneng le tsona li fapane. Le ha pampiri e tšoanang ea ka ntle le pampiri e kahare e sebelisoa, ts'ebetso ea boto e sentsoeng e fapana ka lebaka la sebopeho se fapaneng se fapaneng.

Mefuta e atileng ea bongoana e le 'ngoe e le flute, B Flute le C Flute.

Ka tloaelo motsoako o habeli o tšetsoeng o kenyelletsa lekolilo, e-ba le mafura le ka bc

OLitefiso tsa pampiri ea UR: Boto ea Duplex ea Duplex ea Duplex.

OLitaba tsa pampiri tsa pampiri: Pampiri e tšoeu ea karete e tšoeu, pampiri ea karete e ntšo, pampiri ea Kraft.

OLitepisi tsa pampiri: pampiri ea bonono.

Setšoantšo sa ts'ebetso sa karete ea karete e halikiloeng.

Litlhaloso tse botenya ba karete ea karete e putsoa.

Likopo tsa ho paka

Mofuta oa lebokose o latelang

Ts'ebetso ea Phekolo ea Lefatše

FOIL

Lithako tse matla li tla mebala e fapa-fapaneng, ho kenyelletsa khauta, khauta ea laer, silevera ea silevera ea laser, e ntšo, har'a ba bang.

Wing

Ts'ebetso e buang e bua ka mochini o koahelang lifilimi ho koahela bokaholimo ba taba e hatisitsoeng ka sekhechana sa filimi ea polasetiki.

Ho koata

Concave le Convex ho etsa hore mochini oa khatiso oa liphallelo oa liphallelo oa liphallelo o felisitse lipaterone kapa litlhaku tse tharo tse fapaneng.

Sebaka u

Ka ho omella ka UV le ho folisa, enke e khanya ebile e khethehileng, haholo-holo bakeng sa matšoao a khoebo le litaba tsa khatiso.

Phekolo ea maemo a tloaelehileng joalo ka a latelang