Tali ea tloaelo e hatisoang e nang le lebokose la matsela a matla a pampiri e nang le lebokose le nang le mohala o nang le mohala oa likhoele

Tlhaloso

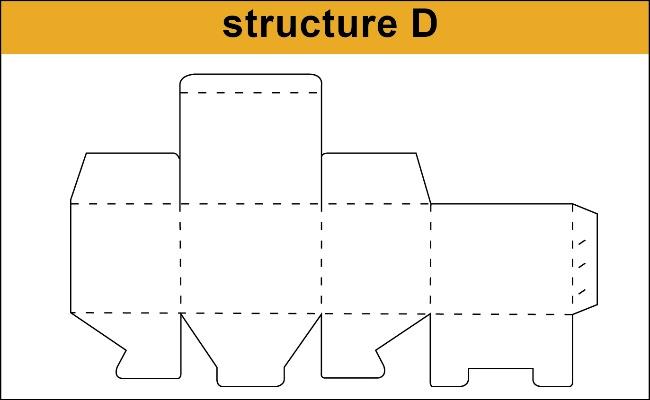

Karolo ea sekoaelo e eketsoa motheong oa sebopeho d ho etsa hore lebokose le tiise ebile le tiile.

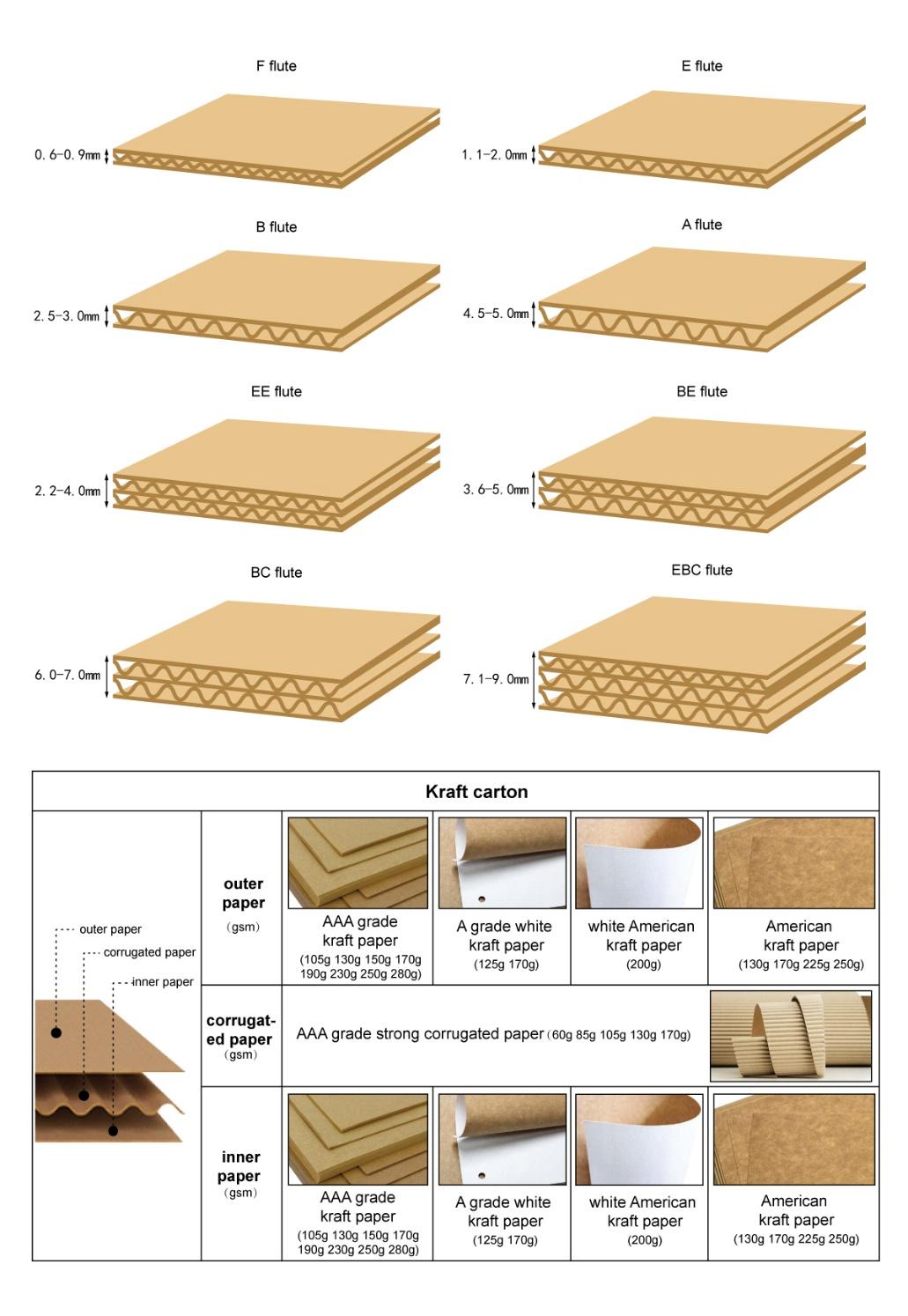

Lintho tsena li ka sebelisa likarolo tse 3 kapa tse 5 tsa karete e matla ea karete ea karete ea ho ikamahanya le lihlahisoa tsa boima bo fapaneng le boholo ba tsona.

Sebopeho se tiile ebile se ka sebelisoa ho sephutheloana sa sehlahisoa, se fana ka liphutheloana le masimo a mang.

BLeseli la ASIC.

| PLebitso la Roduct | Ho tsamaisa lebokose la ho paka | Surface hantle | Glopsy Lague, Matte Lames UV |

| Lebokose Setaele | Moralo oa OEM | LTlhahiso ea Ogo | Clogo ea USTotized |

| Lintho tse bonahalang Sebopeho | Break ea White Break+Board Board/ pampiri ea kraft | ORigin | Ningbo |

| Mofuta oa lekolu | E flute, B Flute, C Flute, BE Thusa | Sam | Amohela mehlala ea moetlo |

| Sebopeho sa sebopeho | REctalele | SNako e lekaneng | 5-8 matsatsi a ho sebetsa |

| Color | C'Mala oa myk,' mala oa tenene | PNako ea Tsamaiso ea Tsamaiso | 8-12 matsatsi a ho sebetsa ka bongata |

| Pho hlapa | Khatiso ea offset,UV Pho hlapa | TPackage ea Ransport | Matla3ply/ 5 plyCarton e koetsoeng |

| Mofuta | Single / tLebokose la khatiso | Moq | 2000pcs |

Litšoantšo tse qaqileng

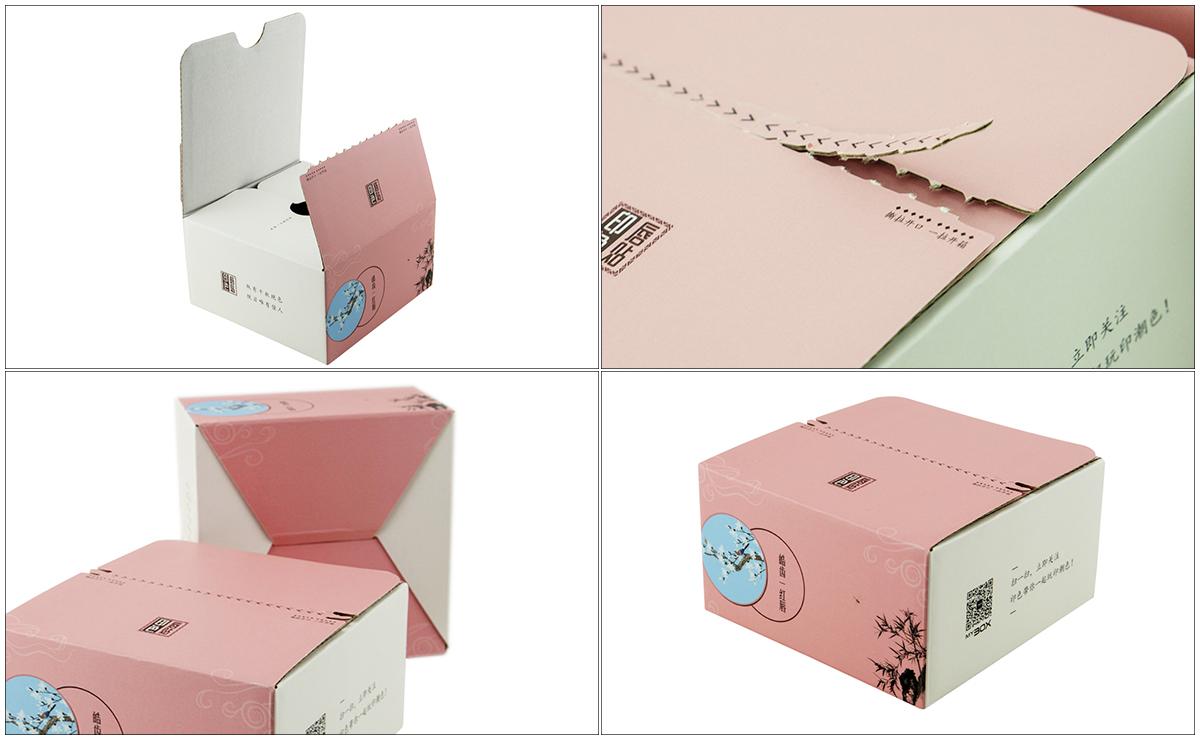

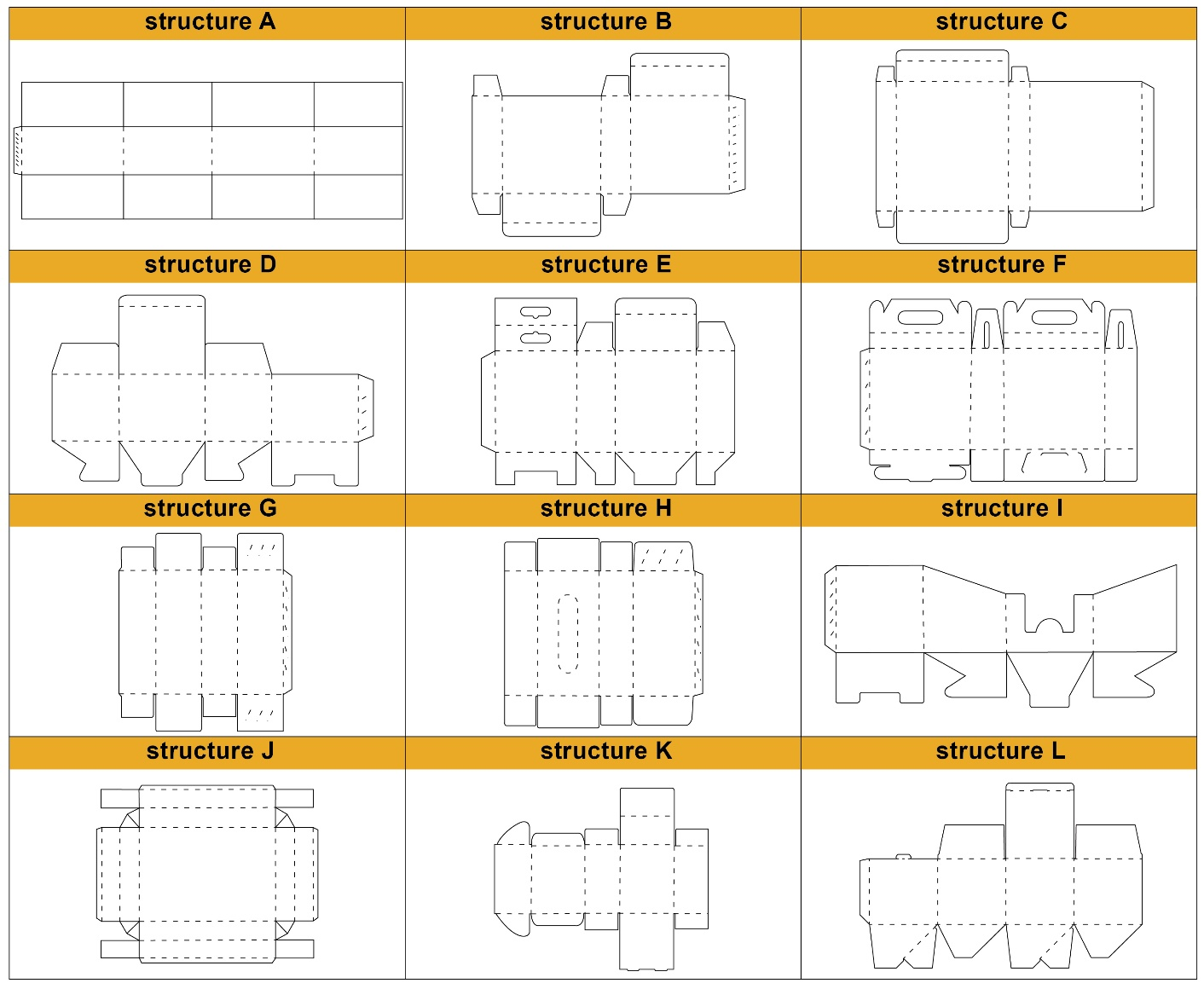

Ho latela litlhoko tsa hau, Moqapi oa sebopeho o tla utsoa sebopeho le boholo ba lebokose. Ho latela setšoantšo sa kaho ea lebokose, o ka rala sephutheloana. Re tla hatisa maqephe ho latela moralo oa hau oa ho theha lebokose le felileng.

Ka kopo buisana le ho buisana le morekisi mabapi le khetho ea lisebelisoa tsa pampiri le mekhoa ea khatiso.

Lihlahisoa tse emetse ho romella thepa li hlophisitsoe hantle.

Sebopeho sa thepa le ts'ebeliso

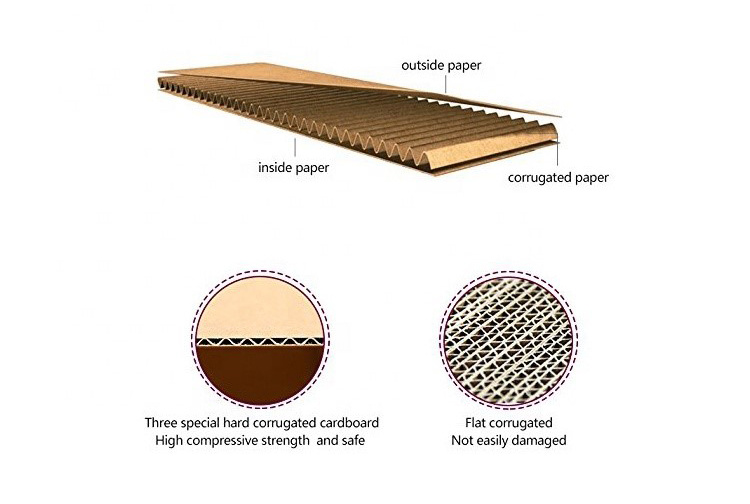

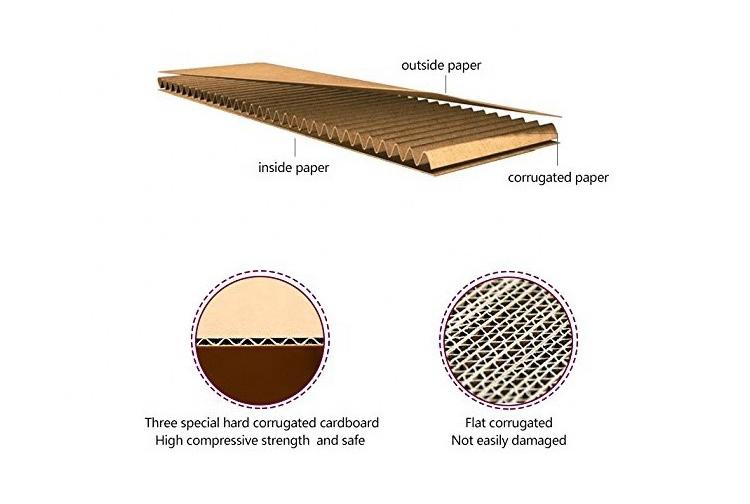

Pampiri ea pampiri e kentsoeng e ka aroloa likarolo tse 3, likarolo tse 5 le lilakane tse 7 ho latela sebopeho se kopaneng. Lihlahisoa tse tharo le tse hlano tsa ply ke lintho tse sebelisoang haholo.

Likarolo tse tharo e le pampiri e kantle, pampiri e mahareng le pampiri e kahare.

Likarolo tse tharo e ka ba boholo ba boholo le boima ba 'mele. Kantle le pampiri e ka hare ho ka hatisoa moralo oa OEM le 'mala.

Mefuta e tloaelehileng ea pampiri ea sefahleho.

Sebopeho se nang le corrrugated Cardboard

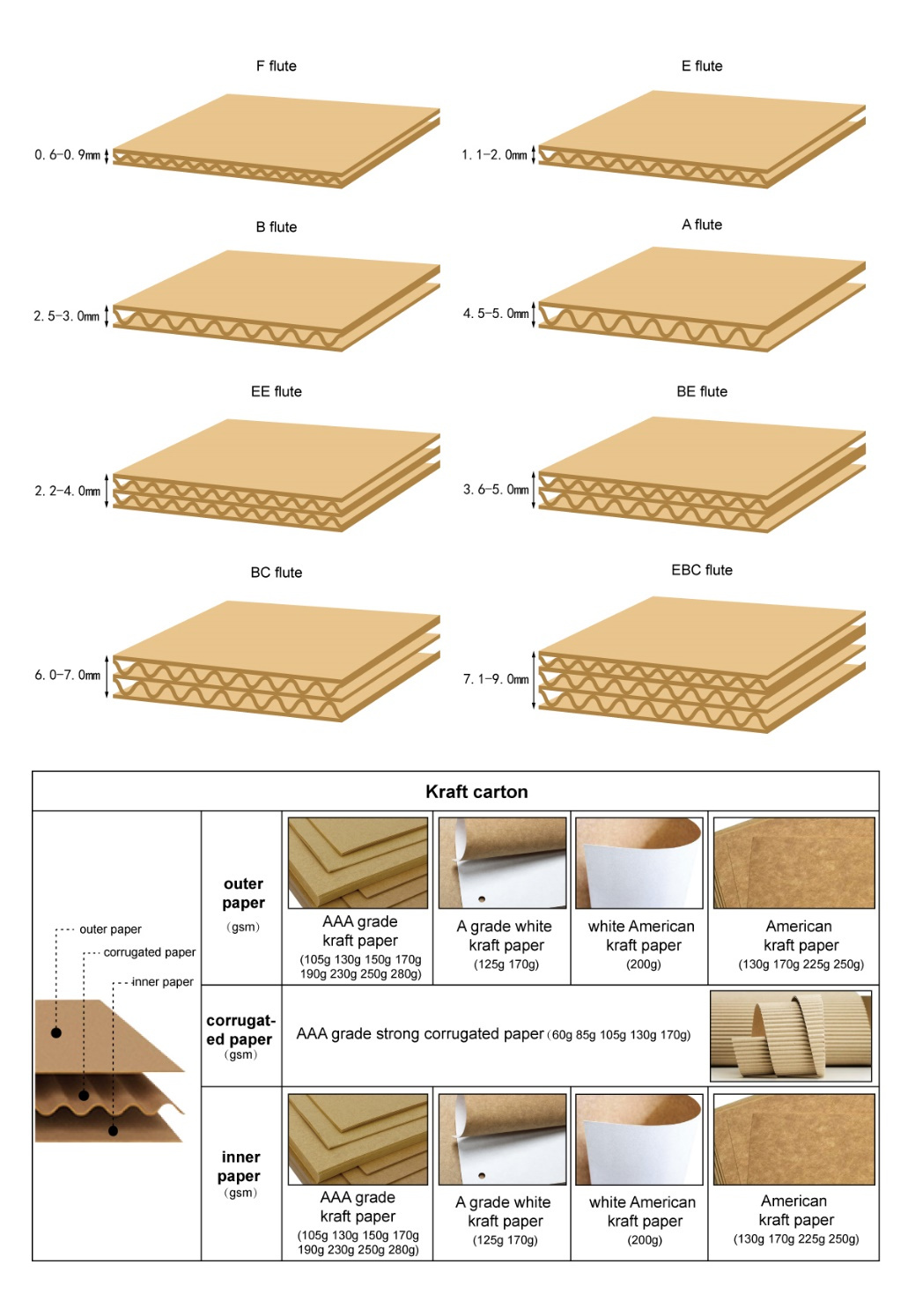

Se latelang ke setšoantšo sa sebano sa botenya ba karete ea karete e halikiloeng. Ka kopo buisana le morekisi mabapi le koluoa e itseng ea thepa le theko.

Likopo tsa ho paka

Litlhaloso tse botenya ba karete ea karete e putsoa.

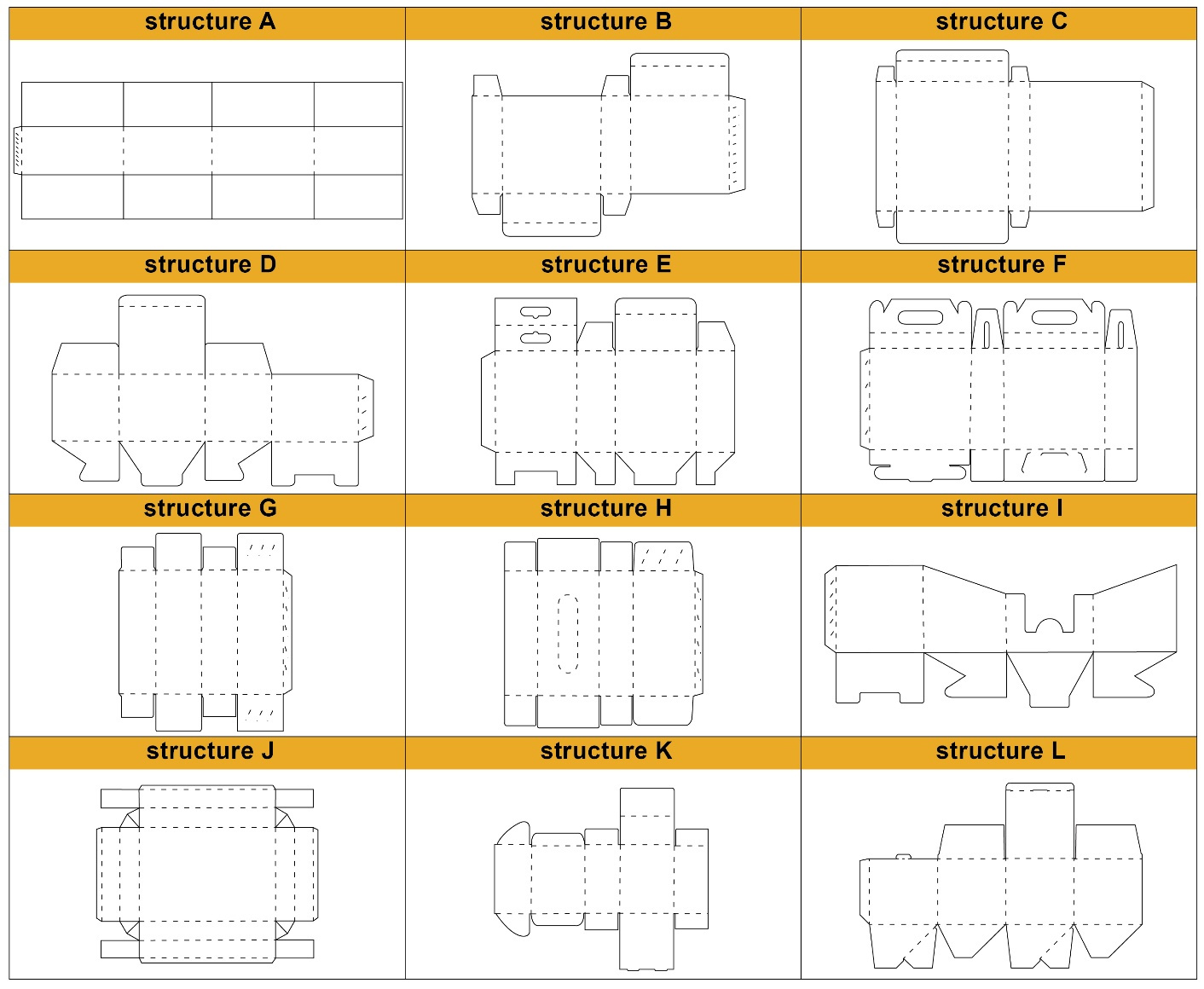

Mofuta oa lebokose le sebaka sa lebokose

Mofuta oa lebokose o latelang

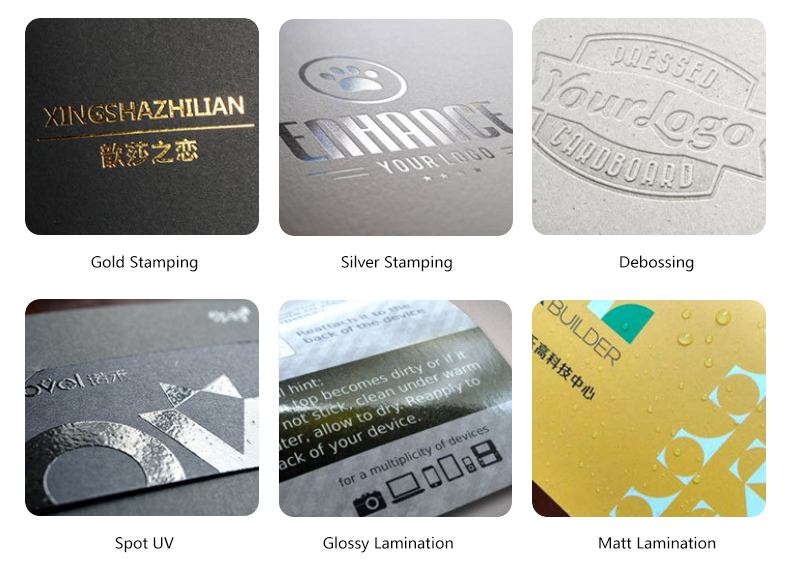

Ts'ebetso ea Phekolo ea Lefatše

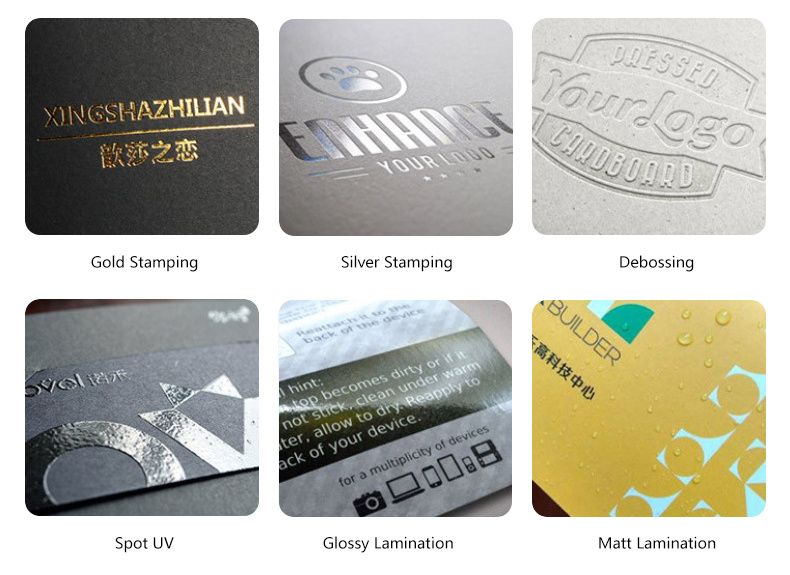

FOIL

Lithako tse matla li tla mebala e fapa-fapaneng, ho kenyelletsa khauta, khauta ea laer, silevera ea silevera ea laser, e ntšo, har'a ba bang.

LSetšoantšo

Ts'ebetso e buang e bua ka mochini o koahelang lifilimi ho koahela bokaholimo ba taba e hatisitsoeng ka sekhechana sa filimi ea polasetiki.

Ho koata

Concave le Convex ho etsa hore mochini oa khatiso oa liphallelo oa liphallelo oa liphallelo o felisitse lipaterone kapa litlhaku tse tharo tse fapaneng.

SPot Uv

Ka ho omella ka UV le ho folisa, enke e khanya ebile e khethehileng, haholo-holo bakeng sa matšoao a khoebo le litaba tsa khatiso.

E tloaelehileng tPhetohoka mokoa o latelang

Potso ea Bareki le Karabo

Ka kopo ikopanye le ts'ebeletso ea bareki bakeng sa tlhaiso-leseling e batsi.

Karabelo ea hau ea lipotso e tla re thusa ho khothaletsa sephutheloana se loketseng ka ho fetisisa.

Pampiri ea pampiri e kentsoeng e ka aroloa likarolo tse 3, likarolo tse 5 le lilakane tse 7 ho latela sebopeho se kopaneng. Lihlahisoa tse tharo le tse hlano tsa ply ke lintho tse sebelisoang haholo.

Likarolo tse tharo e le pampiri e kantle, pampiri e mahareng le pampiri e kahare.

Likarolo tse tharo e ka ba boholo ba boholo le boima ba 'mele. Kantle le pampiri e ka hare ho ka hatisoa moralo oa OEM le 'mala.

Mefuta e tloaelehileng ea pampiri e kantle

Sebopeho se nang le corrrugated Cardboard

Litlhaloso tse botenya ba karete ea karete e putsoa.

Likopo tsa ho paka

Mofuta oa lebokose o latelang

Ts'ebetso ea Phekolo ea Lefatše

FOIL

Lithako tse matla li tla mebala e fapa-fapaneng, ho kenyelletsa khauta, khauta ea laer, silevera ea silevera ea laser, e ntšo, har'a ba bang.

LSetšoantšo

Ts'ebetso e buang e bua ka mochini o koahelang lifilimi ho koahela bokaholimo ba taba e hatisitsoeng ka sekhechana sa filimi ea polasetiki.

Ho koata

Concave le Convex ho etsa hore mochini oa khatiso oa liphallelo oa liphallelo oa liphallelo o felisitse lipaterone kapa litlhaku tse tharo tse fapaneng.

SPot Uv

Ka ho omella ka UV le ho folisa, enke e khanya ebile e khethehileng, haholo-holo bakeng sa matšoao a khoebo le litaba tsa khatiso.

Phekolo ea maemo a tloaelehileng joalo ka a latelang