Lebokose le mebala-bala la Carton e mebala-bala le na le lebokose la karete ea karete ea karete ea karete ea karete

Tlhaloso

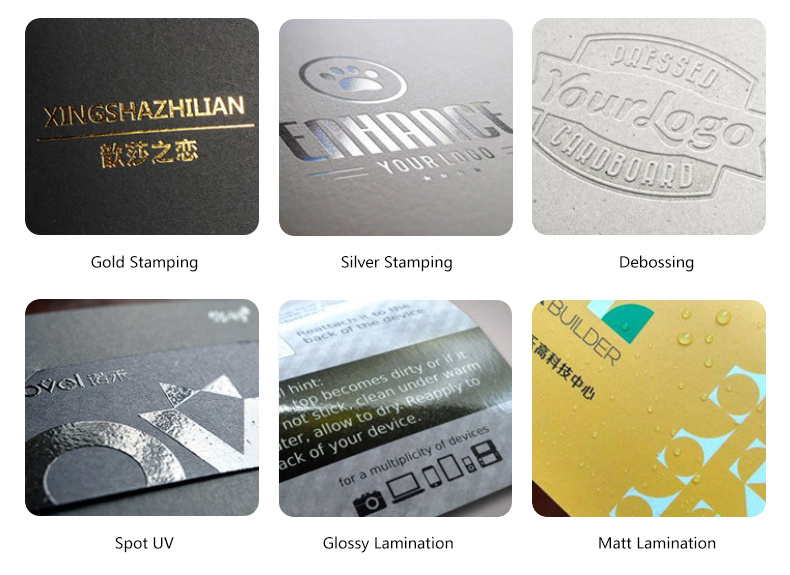

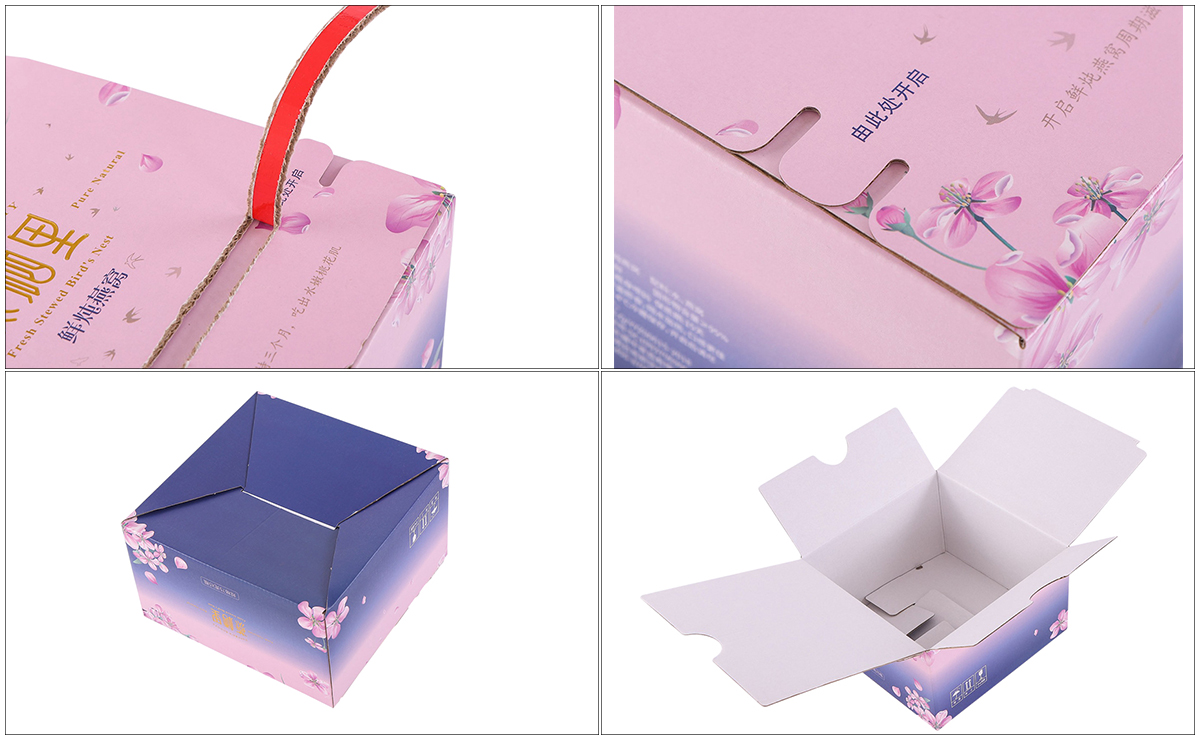

Lebokose le adpts adware khatisong ea Offset, logo e entse ts'ebetso ea khauta, 'me bokaholimo bo koaetsoe ka Mattheu

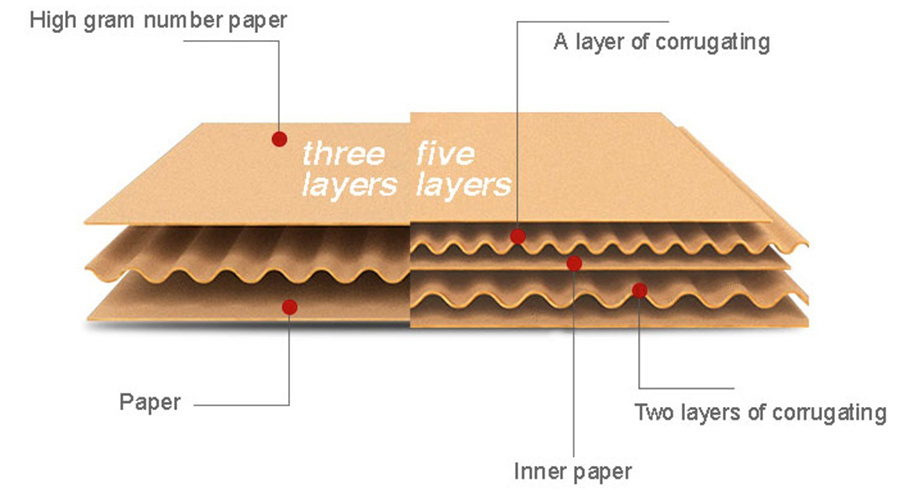

Karolo ea sekoaelo e eketsoa motheong oa sebopeho d ho etsa hore lebokose le tiise ebile le tiile.

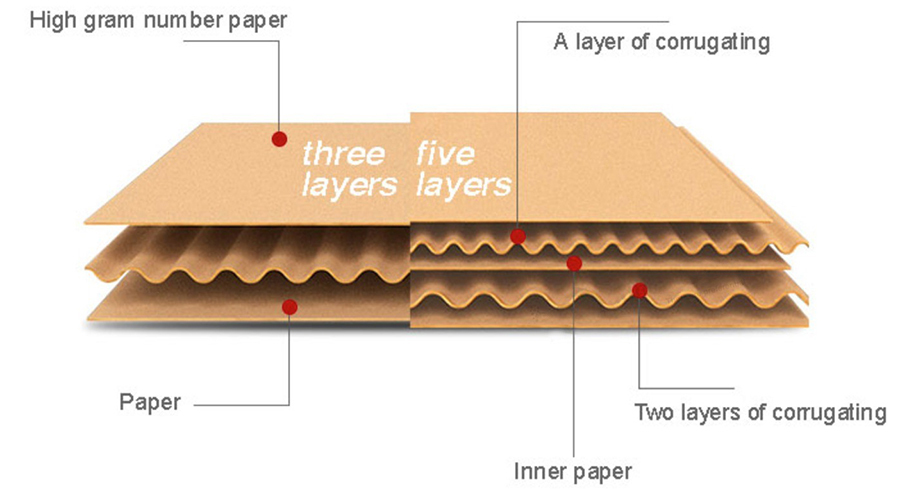

Lintho tsena li na le pampiri e matla e nang le li-papper tse tharo ho 3 ply / 5 ply, ho lekana boima le boholo ba sehlahisoa sa limpho.

E ka sebelisoa bakeng sa ho romella, limpho, ho beha liphutheloana tsa thepa.

Leseli la mantlha

| Lebitso la Product | Lebokose la Zipper Tearton | Bokaholimo bo phahameng | Glopsy Lague, Matte Lames Up UV, sebaka sa khauta |

| Setaele sa lebokose | Lebokose la karete ea karete | Khatiso ea logo | Logo e hlophisitsoeng |

| Sebopeho sa thepa | Break ea White e tšoeu + | Tšimoloho | Ningbo |

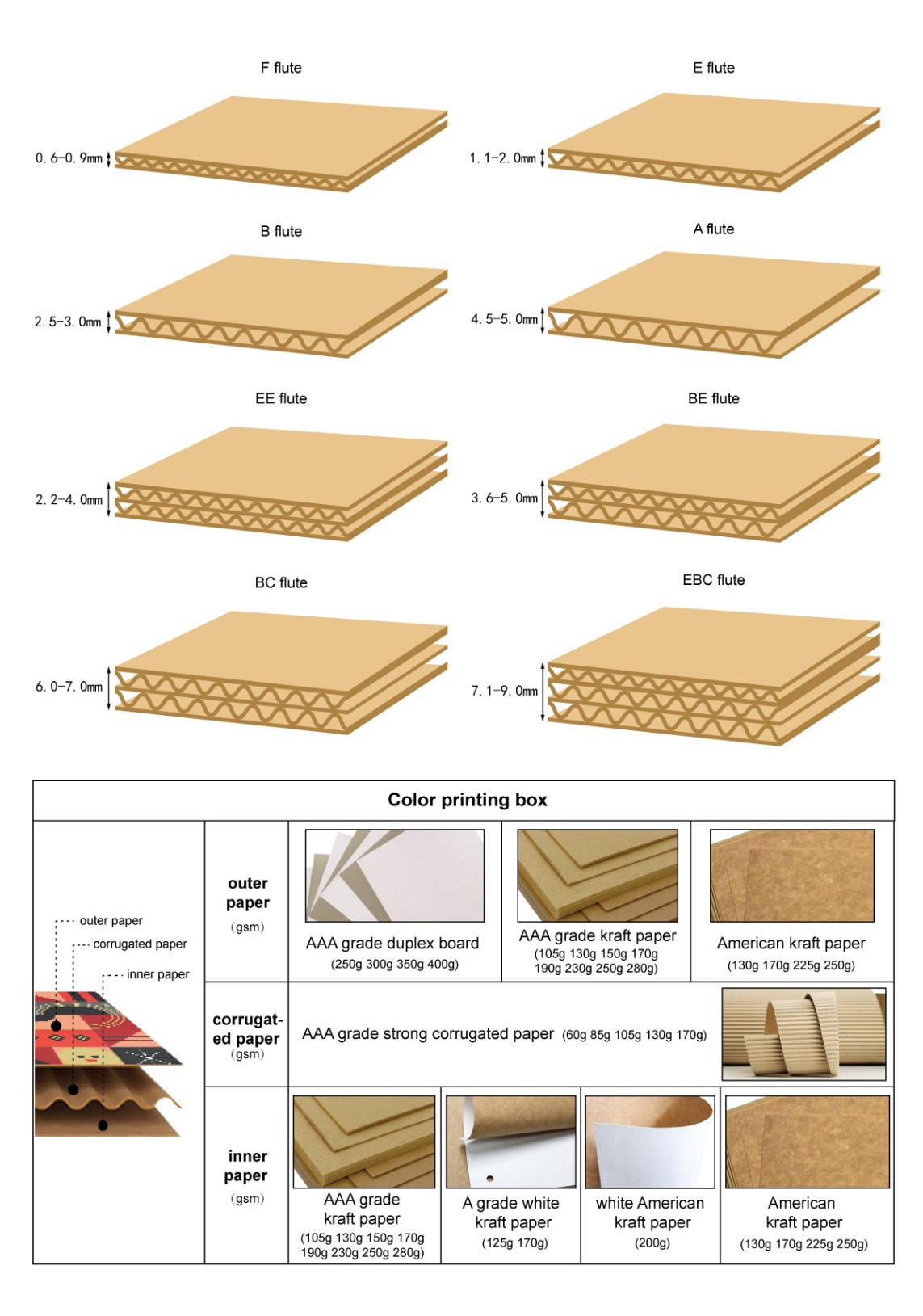

| Mofuta oa lekolu | E flute, B Flute, C Flute, BE Thusa | Sampole | Amohela mehlala ea moetlo |

| Sebopeho sa sebopeho | Rectangle | Nako ea Mohlala | Matsatsi a 5-8 a sebetsa |

| Mmala | 'Mala oa cmyk,' mala oa tenene | Nako ea Khotso | 8-12 matsatsi a ho sebetsa ka bongata |

| TLHOKOMELISO | TLHALOSO EA TLHOKOMELISO | Sephutheloana sa lipalangoang | Li-carton e matla ea 5 ea li-curugated |

| Mofuta | Lebokose le leng le le leng / la ho hatisa ka thoko | Moq | 2000pcs |

Litšoantšo tse qaqileng

Moqapi oa sebopeho o tla taka boholo le sebopeho sa lebokose ho ea ka litlhoko tsa hau.

Re tla u fa setšoantšo sa mofuta oa mahala bakeng sa boqapi ba hau.

Bakeng sa ho etsa lebokose le felileng, re tla hatisa ho latela moralo oa hau.

Sebopeho sa thepa le ts'ebeliso

Mesebetsi ea likarete tse halikiloeng tse bolokiloeng ka libopeho tse fapaneng le tsona li fapane. Le haeba tšobotsi e tšoanang ea pampiri ea kantle le lipampiri tse ka hare li sebelisoa, ts'ebetso ea likarete tse entsoeng ka pokello e thehiloeng ka sebopeho sa pampiri e khaotsoeng le tsona li fapane.

Mefuta e atileng ea bongoana e le 'ngoe e le flute, B Flute le C Flute.

Ka tloaelo motsoako o habeli o tšetsoeng o kenyelletsa lekolilo, e-ba le mafura le ka bc

Mefuta e tloaelehileng ea pampiri e kantle.

Setšoantšo sa ts'ebetso sa karete ea karete e halikiloeng.

Litlhaloso tse botenya ba karete ea karete e putsoa.

Likopo tsa ho paka

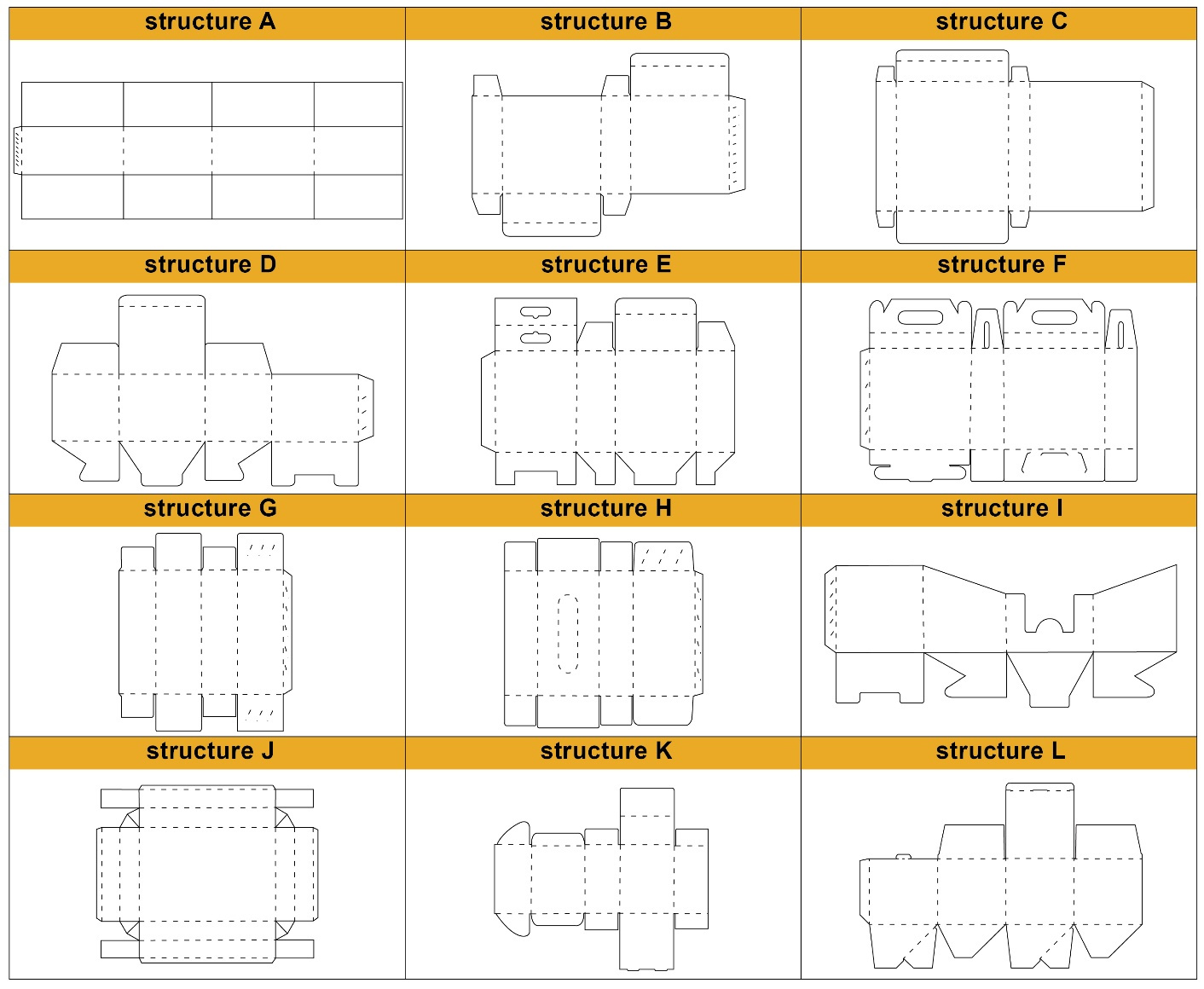

Mofuta oa lebokose le sebaka sa lebokose

Mofuta oa lebokose o latelang

Ts'ebetso ea Phekolo ea Lefatše

FOIL

Ho na le mefuta e mengata ea methapo ea kutlo, ho kenyelletsa le khauta, silevera ea laser, silevera ea silevera ea laser, e khubelu, e putsoa, e khubelu, e khubelu, e khubelu, e khubelu, e putsoa, e khubelu

LSetšoantšo

Ts'ebetso e buang e bua ka mochini o koahelang lifilimi ho koahela bokaholimo ba taba e hatisitsoeng ka sekhechana sa filimi ea polasetiki.

Ho koata

Concave le Convex ho etsa hore mochini oa khatiso oa liphallelo oa liphallelo oa liphallelo o felisitse lipaterone kapa litlhaku tse tharo tse fapaneng.

SPot Uv

Ka ho omella ka UV le ho folisa, enke e khanya ebile e khethehileng, haholo-holo bakeng sa matšoao a khoebo le litaba tsa khatiso.

Phekolo e tloaelehileng ea tlhahoka mokoa o latelang

Potso ea Bareki le Karabo

PLits'ebetso tsa moreki bakeng sa tlhaiso-leseling e batsi.

YouKarabelo ea lipotso e tla re thusa ho khothaletsa sephutheloana se loketseng ka ho fetisisa.

Mesebetsi ea likarete tse halikiloeng tse bolokiloeng ka libopeho tse fapaneng le tsona li fapane. Le haeba tšobotsi e tšoanang ea pampiri ea kantle le lipampiri tse ka hare li sebelisoa, ts'ebetso ea likarete tse entsoeng ka pokello e thehiloeng ka sebopeho sa pampiri e khaotsoeng le tsona li fapane.

Mefuta e atileng ea bongoana e le 'ngoe e le flute, B Flute le C Flute.

Ka tloaelo motsoako o habeli o tšetsoeng o kenyelletsa lekolilo, e-ba le mafura le ka bc

Mefuta e tloaelehileng ea pampiri e kantle.

Setšoantšo sa ts'ebetso sa karete ea karete e halikiloeng.

Litlhaloso tse botenya ba karete ea karete e putsoa.

Likopo tsa ho paka

Mofuta oa lebokose o latelang

Ts'ebetso ea Phekolo ea Lefatše

FOIL

Ho na le mefuta e mengata ea methapo ea kutlo, ho kenyelletsa le khauta, silevera ea laser, silevera ea silevera ea laser, e khubelu, e putsoa, e khubelu, e khubelu, e khubelu, e khubelu, e putsoa, e khubelu

Wing

Ts'ebetso e buang e bua ka mochini o koahelang lifilimi ho koahela bokaholimo ba taba e hatisitsoeng ka sekhechana sa filimi ea polasetiki.

Ho koata

Concave le Convex ho etsa hore mochini oa khatiso oa liphallelo oa liphallelo oa liphallelo o felisitse lipaterone kapa litlhaku tse tharo tse fapaneng.

Sebaka u

Ka ho omella ka UV le ho folisa, enke e khanya ebile e khethehileng, haholo-holo bakeng sa matšoao a khoebo le litaba tsa khatiso.

Phekolo ea maemo a tloaelehileng joalo ka a latelang